Rugged Tablets

Rugged tablets have ushered in a new segment of mobility. Gone are the days of...

Read More

Zebra ZT600 Series Industrial Printers

PRINTERS—ZT600 Bring intelligent and industrial brawn to your facility with the ZT600 and ZT500 industrial...

Read More

Zebra Long-Range RAIN RFID Reader

Handhelds – MC3390R RFID Reader Zero in on distant items with zero effort with the...

Read More

RFID Handhelds

Future-Proof Your Warehouse with RFID Whatever type of warehouse operation you’re managing, manual processes and...

Read More

We’ve Got RFID Hardware, Software & Services Down To A Science

5thWave & Zebra Technologies: We’ve Got RFID Hardware, Software & Services Down To A Science...

Read More

The Role of Mobile Device Staging in Retail: Preparing Devices for Seamless In-Store Data Collection

When it comes to enhancing retail operations, there’s always a question of how to keep...

Read More

Improving Supply Chain Visibility with Mobile Barcode Label Printers!

What if you could track every product in your supply chain in real-time, from warehouse...

Read More

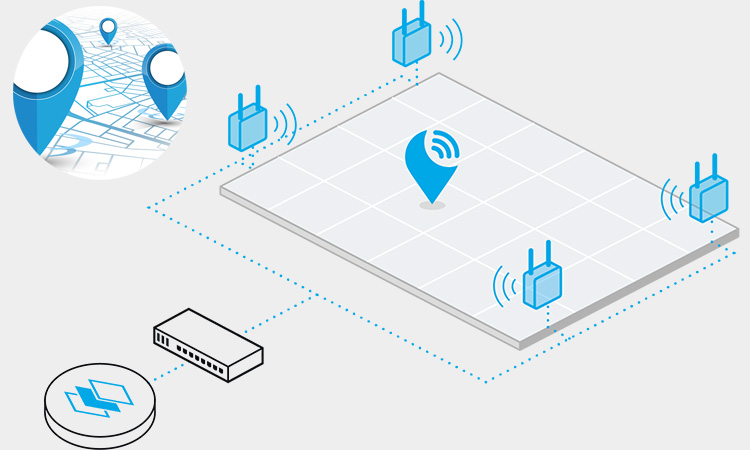

RTLS for Retail: How Real-Time Location Data Enhances Customer Experience!

In the competitive retail landscape, managing inventory, optimizing store layouts, and providing excellent customer service...

Read More

How Mobile Apps are Transforming Data Collection in Healthcare!

In today’s healthcare landscape, the ability to collect and manage data efficiently is crucial for...

Read More

Why Businesses Should Use a Real-Time Locating System for Asset Tracking

Managing assets efficiently is a challenge for many businesses. Tools, equipment, and even staff can...

Read More